Screen printing on fabric is all about pushing ink through a stenciled mesh screen to lay down a design right onto a piece of clothing. It’s a hands-on craft, the secret behind those classic, bold graphic tees you see everywhere that just seem to last forever. Think of it as a beautifully refined stenciling process born from the same grit and ingenuity that defines Brooklyn's creative soul.

The Soul of Print From Bushwick Lofts to Boutique Tees

Picture the buzzing, creative energy of an artist’s loft in Brooklyn—that's where the soul of screen printing really thrives. This isn't just another printing method; it’s the pulse of the borough's independent spirit. It’s the through-line connecting the raw, rebellious vibe of DIY punk flyers plastered on Bedford Avenue walls in the '90s to the high-quality, iconic tees you see at the Brooklyn Flea and in local band merch today.

Choosing to screen print is a statement. It’s what creators turn to when they want that authentic, human touch that turns a basic t-shirt into something special, a piece of wearable art. Every single print is a direct transfer of an idea onto fabric, forging a real connection between the artist and the person who wears it.

A Craft Fueling Creativity and Commerce

This beautiful mix of artistry and practicality has turned screen printing into a powerhouse for creative entrepreneurs. It’s the engine that drives countless small businesses, from weekend pop-ups under the Williamsburg Bridge to market stalls in Bed-Stuy. It gives them the power to create professional-grade gear that builds a dedicated following and a real community.

Screen printing perfectly captures the one-of-a-kind ethos of Brooklyn's creative scene—it’s not just about making a product, but about leaving a mark. It champions durability and vibrant expression in a world of fleeting trends.

The ripple effect of this craft goes far beyond local studios. Across the country, the custom screen-printing industry is a lifeline for thousands of small and medium-sized shops, proving its role as a key economic player. In fact, the industry's revenue was projected to hit around $12.8 billion in 2025, a powerful number that speaks to its enduring popularity for t-shirts, sportswear, and promotional gear. You can discover more insights on the screen printing market's growth to see just how big it is. This is more than an art form; it’s the foundation for countless creative businesses nationwide.

The Creative Journey of a Screen Printed Tee

Every great t-shirt starts as a spark. It could be an idea that hits you on the L train, a quick sketch in a notebook, or a bold design you’ve been perfecting on your laptop. That initial flash of creativity is the soul of the whole project. So, what is screen printing on fabric, really? It’s the craft of taking that spark and turning it into something real—a piece of art you can wear.

This isn't some sterile, automated process. It’s a hands-on journey, a beautiful dance between art and technique where every step builds on the last. Think of it less like an assembly line and more like a painter prepping a canvas. It’s how a simple piece of clothing becomes a statement.

Step 1: Preparing the Screen

Long before a drop of ink touches a shirt, the screen needs to be prepared. This is where the magic begins, and honestly, it’s the most critical part of the whole shebang. The screen, which is just a fine mesh pulled tight over a frame, is your canvas.

First, it gets a careful, even coating of a light-sensitive liquid called emulsion. This bright green or blue goo is what will eventually hold your design. The coated screen is then whisked away to a dark room to dry, completely shielded from any light that could spoil the process.

Step 2: Burning the Design

Once the screen is bone dry, it's time to bring your design into the picture. Your artwork, printed in solid black ink on a clear film, is laid flat against the emulsion-coated screen. The whole setup then gets blasted with a super-bright light.

This is where the real alchemy happens. The intense light hardens the emulsion everywhere except for the parts covered by your black design. Those areas stay soft. After a few minutes under the light, a quick spray of water washes away the unhardened emulsion, leaving behind a perfect stencil of your design embedded in the mesh. Your vision is now literally etched into the screen.

Step 3: Pulling the Ink

Now for the fun part—the moment of creation. The screen is locked into place, hovering just above the t-shirt. A generous line of thick, colorful ink is laid down at one end of the screen.

Using a tool called a squeegee, the printer makes one clean, firm pass, pulling the ink across the entire design. This single motion pushes the ink through the open mesh of your stencil and directly onto the fabric. When the screen is lifted, your design is there—crisp, vibrant, and perfectly printed.

That single pull of the squeegee is what gives screen printing its soul. The angle, the pressure, the speed—it's all part of the artisan's craft, making each print consistent yet beautifully imperfect.

Feeling inspired? For anyone wanting to get their hands dirty, knowing these steps is the first move. If you're ready to start your own creative project, you can learn more about how to screen print t-shirts at home.

Step 4: Curing the Final Print

The job isn't done until the ink is set. The freshly printed tee takes a trip through a high-heat conveyor dryer, which cures the ink and permanently locks it into the fabric. This blast of heat is what makes the design durable enough to withstand countless washes without cracking or fading. It’s the final step that turns a cool print into a piece of wearable art that will last for years.

Choosing Your Ink: The Personality of Your Print

The ink you choose is so much more than just a color—it's the soul of your design. It dictates not only how your print looks but, just as importantly, how it feels to the touch. For anyone creating apparel, especially here in Brooklyn where every detail tells a part of the story, picking the right ink is like casting the lead actor in your play.

Each ink type has its own personality, a unique way it bonds with the fabric to bring your vision to life. This single choice can turn a simple t-shirt into a statement piece with a real attitude. Let's get to know the three main characters that will define your print's voice.

Plastisol: The Bold Rockstar

Think of plastisol ink as the confident, swaggering rockstar of the printing world. It's a plastic-based ink that doesn't soak into the fabric. Instead, it sits right on top, creating a durable, slightly raised layer of color. This is why you get those incredibly vibrant, opaque colors that just pop, especially on dark-colored shirts.

Plastisol is the go-to when your design needs to scream from the rooftops. It’s perfect for a Dumbo startup’s crisp, brilliant logo or a Bushwick band's tour merch that has to stand out from the back of the venue. Its consistency makes it incredibly reliable, and its bright finish is made to grab attention.

Water-Based: The Indie Artist

If plastisol is the loud rockstar, then water-based ink is the soulful indie artist. This ink is much thinner and works by soaking directly into the garment's fibers. Rather than sitting on the surface, it literally becomes a part of the shirt, dyeing the material with your design.

The result is a print that's incredibly soft and breathable—you often can't even feel it. This method is perfect for achieving that sought-after vintage, worn-in look right off the bat. It's the ink you’d choose for a Williamsburg boutique wanting a subtle, high-end feel or an artist creating a limited-edition run with a soft, lived-in vibe.

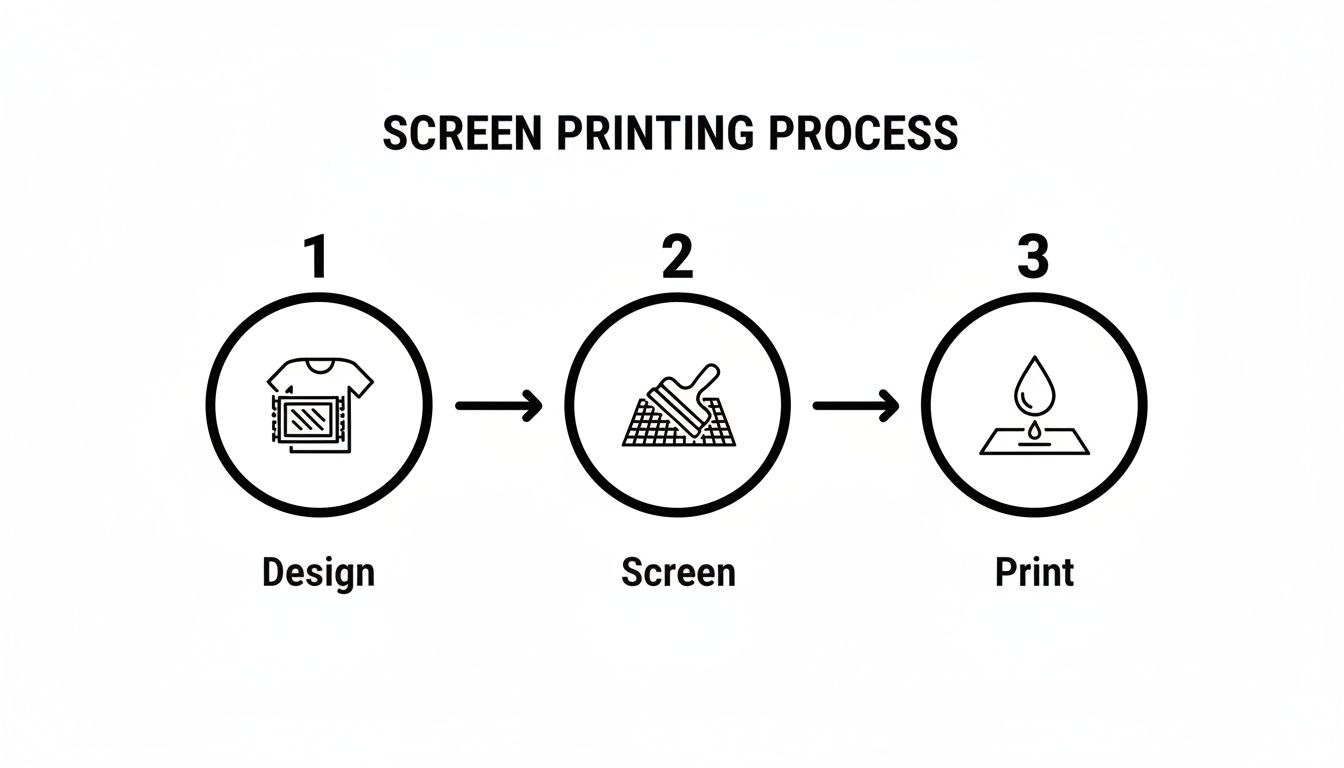

This simple infographic captures the journey from initial idea to the finished piece.

It shows how each essential stage—designing, burning the screen, and finally printing—comes together in the screen printing process.

Discharge: The Rebel Alchemist

Now, discharge ink is the true rebel alchemist of the bunch. It’s a special kind of water-based ink containing an activator that removes the fabric’s original dye instead of just laying color on top. It basically bleaches your design into the shirt, revealing the natural, off-white color of the cotton underneath. You can also mix pigments into it to re-dye the fabric a new color in one go.

This chemical magic results in the softest print imaginable because there is no ink layer left at all—just the re-dyed fabric itself. It’s the ultimate choice for a premium, absolutely no-feel finish on 100% cotton shirts.

To help you decide, here’s a quick breakdown of how these inks stack up against each other.

Ink Comparison: Plastisol vs. Water-Based vs. Discharge

| Ink Type | Feel on Fabric | Vibrancy | Best For |

|---|---|---|---|

| Plastisol | Slightly raised, smooth, plastic-like feel. | Very high, opaque, and bright, especially on darks. | Bold graphics, sports jerseys, dark garments. |

| Water-Based | Super soft, breathable, becomes part of the fabric. | More subtle, vintage, or "washed" look. | Premium/fashion tees, light-colored fabrics. |

| Discharge | Zero feel, as it re-dyes the cotton fibers. | Bright on darks, but colors can vary slightly. | High-end apparel, vintage looks on 100% cotton. |

Ultimately, choosing your ink is a huge creative decision. Do you want the loud declaration of plastisol, the gentle whisper of water-based, or the innovative magic of discharge? Whatever you pick will give your Brooklyn-inspired creation its authentic, unforgettable voice.

Why Brooklyn's Makers Swear By Screen Printing

In a borough that lives and breathes authenticity, Brooklyn's creators—the artists, makers, and brand builders—need a medium that’s as real and resilient as they are. In a world full of fast fashion and digital fads, screen printing gives you something you can actually hold onto, something that lasts. It's the go-to method for making a real impact, turning a simple piece of clothing into a wearable piece of local culture.

This isn't just about slapping a design on a shirt; it's about crafting an emblem for a community. Whether it's for a new brewery in Gowanus or that beloved record store in Park Slope, screen printed apparel becomes a walking billboard for local pride. It's the one method that lets these businesses create high-quality gear that feels both premium and completely grassroots at the same time.

The Unmatched Durability of a Brooklyn Brand

A screen printed design isn't just sitting on top of the fabric—it's practically bonded to it. When the ink is cured correctly, it fuses with the fibers, creating a print that’s built to survive the hustle of city life. It’s not going to peel, crack, or fade into oblivion after a few trips through the laundry.

That kind of durability means the story you’re telling with your design sticks around as long as the shirt itself. It’s an interesting fact that some of the first pop-art screen prints by artists like Andy Warhol, who had deep ties to the city’s art scene, were done in Brooklyn lofts. That spirit of creating lasting, accessible art is still alive in every tee printed here.

Colors That Pop with Sidewalk-Stopping Vibrancy

Brooklyn is anything but boring, and the clothes made here need to match that energy. Screen printing delivers a punch of color vibrancy that digital methods just can't always touch. The thick, rich layers of ink create a bold, tactile quality you can literally see and feel.

The sheer intensity of screen printed colors gives a design an undeniable presence. It’s the difference between a graphic that just sits on a shirt and one that practically jumps off it, catching eyes from across a crowded street.

This powerful visual impact is exactly why screen printing remains a global powerhouse for textiles. In 2024, fabrics made up over 56% of the entire screen printing services market, which just goes to show that when it comes to apparel, this method is still king. Learn more about screen printing's market dominance and see why it continues to be the trusted choice.

Cost-Effectiveness: The Engine for Indie Brands

Let's talk numbers. Screen printing is the great equalizer for independent creators. Sure, the initial setup for a design takes a bit of work, but the cost per shirt plummets as you print more. This scalability is the perfect fuel for launching a brand or getting merch ready for a band's tour.

It makes a run of 50 or 100 professional-quality tees completely achievable, empowering local entrepreneurs to bring their vision to life without needing a massive budget. It’s the smart, strategic play that powers the independent spirit defining Brooklyn's entire creative scene.

Screen Printing Versus Modern Digital Methods

To really get why screen printing is so special, it helps to see how it stacks up against today's digital methods. Each technique has its own vibe, just like the different creative scenes scattered across Brooklyn. It’s all about finding the right process for the soul of your project.

Think of screen printing as the vinyl record of the apparel world—classic, rich, and built to last. It’s the go-to for that run of 100 tees for your band’s next tour or the launch of a new clothing line. There’s a warmth and permanence to it that just feels authentic.

The Digital Alternatives

Digital methods, on the other hand, offer a totally different kind of creative freedom. They’re built for a world that loves speed, complexity, and one-of-a-kind pieces—a perfect match for the fast-paced, hyper-individual energy buzzing around a Dumbo tech startup.

Let's look at the two main digital players:

-

Direct-to-Garment (DTG) Printing: This is like using a high-end inkjet printer, but for fabric. It sprays ink that soaks right into the cotton fibers, letting you print photorealistic images with millions of colors and incredible detail.

-

Heat Transfer Printing: Think of this as creating a high-quality, custom iron-on. Your design gets printed onto a special transfer material, which is then fused onto the garment with heat and pressure. It’s perfect for adding a player’s name to a jersey or working with tricky synthetic fabrics.

Choosing Your Creative Path

So, how do you decide? Screen printing is the undisputed champ for bold, vibrant designs made in batches. It gets more affordable the more you print and the durability is second to none, making it the foundation of merch culture. It’s for the brand builder who wants to make a lasting mark.

DTG printing, however, is all about individuality. It’s the perfect solution for that single, stunningly detailed masterpiece or for testing a bunch of different designs without being forced to buy in bulk. No minimums means total creative freedom.

If you're curious to learn more about how this digital magic works, we've got a full breakdown on what is Direct-to-Garment printing.

Heat transfer carves out its own niche in personalization—think custom names and numbers for the local sports team or unique graphics on materials where other methods just don't work.

In the end, knowing what is screen printing on fabric is about understanding when its timeless craft is the perfect voice for your vision, and when a modern digital tool can bring a different kind of idea to life.

Preserving the Art: How to Care For Your Printed Garment

That screen-printed tee isn't just another shirt in your drawer. It’s a piece of wearable art, a tangible piece of Brooklyn's soul. So, taking care of it isn't a chore—it’s about preserving that story and honoring the hands that brought it to life. A few simple habits will keep that design looking as sharp and vibrant as the day you got it.

With every wash, you have the chance to keep the story going. The right care makes all the difference, ensuring your favorite tee stays in rotation for years, its message loud and clear.

Simple Rituals for Lasting Vibrancy

You don’t need any special tricks to protect your printed fabric, just a bit of intention. Here are the three golden rules I always share with people.

First, always wash your garment inside out. This is non-negotiable. Turning it inside out creates a protective barrier, shielding the print from the rough-and-tumble friction of other clothes and the machine itself.

Second, stick with cold water. Hot water is the enemy of a good print; it can make the ink soften and the fabric shrink, leading to that dreaded faded and cracked look. Cold water is kinder to the ink and the fibers, locking in the color and keeping the design crisp.

Preserving your screen-printed art is about respecting the craft. Simple care practices honor the maker's work and ensure the piece remains a vibrant part of your collection, telling its Brooklyn story for years.

Finally, step away from the high-heat dryer setting. That intense blast of heat is the fastest way to ruin a print, causing it to peel and crack almost overnight. Tumble dry on low, or better yet, let it air dry. It’s the single best thing you can do for longevity.

For a deeper dive, we’ve put together a complete guide on how to wash graphic tees to keep them looking brand new.

Common Screen Printing Questions, Answered

Alright, so you've got a killer design inspired by the streets of Brooklyn, and you're ready to see it on a shirt. Awesome. But before you jump in, a few practical questions usually pop up. Let's clear the air so you can move forward and turn that idea into something people can actually wear.

How Many Colors Can I Realistically Use?

Think of each color in your design as a separate layer, each needing its own custom screen. It's a very hands-on process. For that reason, designs with 1 to 4 colors are really the sweet spot. They keep things looking crisp and classic without getting overly complicated or expensive.

Now, that doesn't mean you're boxed in. A seasoned printer has tricks up their sleeve. One of the coolest is halftoning, which uses tiny dots of a single ink color to create the illusion of different shades and even gradients. It’s a clever way to add depth and a bit of texture without bumping up the screen count.

Can Screen Printing Actually Be Eco-Friendly?

Brooklyn's creative spirit isn't just about looking good; it's about doing good, too. The screen printing world has come a long way, and making a sustainable choice is more accessible than ever. Did you know that some of the first organized recycling programs in the US started right here in Brooklyn? That same pioneering spirit of sustainability is alive in many print shops today.

The key is to find a printer who's intentional about their materials. Ask if they use water-based inks, which are a fantastic alternative to traditional, plastic-heavy inks. Many shops also use soy-based solvents to clean their screens. Making these small choices adds up, ensuring your project reflects a more mindful approach to creation.

Understanding the 'why' behind screen printing practices empowers you to make choices that align with your vision. Minimums aren't a barrier; they are the gateway to making your art accessible while maintaining professional quality.

What's the Deal with Minimum Orders?

Screen printing is a craft, and the setup is no joke. Burning a perfect screen for every single color in a design takes time, skill, and materials. It's a significant upfront effort before the first shirt is even printed.

To make this whole process viable, printers set minimum orders, usually somewhere around 24 to 50 pieces. This threshold is what makes screen printing the go-to method for creating a batch of high-quality, professional-grade apparel. It ensures every single piece is a faithful representation of your art, ready to get out there and build a following.

Ready to bring your own piece of Brooklyn to life? The Brooklyn Initiative specializes in creating limited-edition, screen-printed tees that tell a story. Start your creative journey with us today.