Ever dreamed of taking your most detailed digital masterpiece and transferring it directly onto fabric, with all the vibrancy and nuance of a fine art print? That’s the reality of Direct-to-Garment (DTG) printing. It’s a bit like magic, bridging the gap between your screen and a wearable canvas.

This process uses specialized inkjet technology to spray eco-friendly, water-based inks straight into the cotton fibers of a garment. The result is a print that’s not just on the shirt, but in it—creating a soft, breathable finish that’s as stunningly detailed as the original art.

Your Digital Canvas: What Is Direct-to-Garment Printing?

Picture your trusty office printer. Now, imagine swapping the paper for a fresh t-shirt and hitting 'print' on your boldest design. At its heart, that’s Direct-to-Garment (DTG) printing. It’s a modern technique where a digital image is printed directly onto apparel, much like a document.

Where older methods often lay a thick, plastic-y layer of ink on top of the fabric, DTG is different. It soaks the ink right into the garment’s fibers. This gives you a print that feels incredibly soft to the touch and moves with the fabric, because it has truly become part of the shirt itself.

A Tool for the Modern Creator

For any artist in a place like Brooklyn—where inspiration is everywhere, from the street murals to the skyline—this technology is a game-changer. It gives independent creators the power to bring incredibly complex, full-color designs to life without the old-school barriers of traditional printing.

Think photorealistic images, subtle color gradients, and tiny, intricate details, all reproduced with breathtaking accuracy. You can literally launch a brand with nothing more than a great idea and a high-resolution digital file. This kind of freedom is exactly why DTG has become the go-to for so many of today's creative entrepreneurs.

Did you know Brooklyn was once home to the world's largest mural? For years, the Domino Sugar Factory's massive water tanks were painted by artists, a testament to the borough's love for large-scale, intricate public art. DTG printing echoes this spirit, allowing for a similar level of detail on a much smaller canvas.

To get a clearer picture, here’s a quick breakdown of what makes DTG stand out.

DTG Printing At A Glance

| Characteristic | What It Means for Your Art |

|---|---|

| Printing Method | Digital inkjet printer applies ink directly to fabric. |

| Color Capability | Full-color spectrum; millions of colors possible. |

| Ideal Fabric | Best on 100% cotton; works well on high-cotton blends. |

| Print Feel | Extremely soft and breathable, as ink soaks into fibers. |

| Best For | Small batches, on-demand printing, and one-offs. |

| Design Complexity | Perfect for photos, gradients, and intricate details. |

This table captures the essence of DTG: it’s built for detail, flexibility, and quality.

Why It Matters for Your Brand

The real beauty of this method is in its flexibility. There are no punishing setup costs or minimum order quantities holding you back. This unlocks the power of on-demand production, which is perfect for testing a new design, creating a one-of-a-kind piece for a special event, or building a sustainable business that only produces what it sells.

For a Brooklyn-based brand, this means you can be as agile and dynamic as the city you call home.

The Spark: A Brooklyn-Sized Idea

Every great tool has an origin story, a moment when someone asks, "What if there's a better way?" For direct-to-garment printing, that question echoed through the creative world of the 90s: what if we could print on a t-shirt as easily as we print on paper?

This wasn't just a technical question; it was about giving power back to the artist. The first big answer came in 1996 with a machine fittingly named the 'Revolution.' It was the first commercially available DTG printer, proving that the inkjet concept wasn't just for paper. It was the seed of a whole new way to make apparel. You can dig deeper into this history and see the original patent filed by its inventor, Matthew Rhome, in this brief history of direct to garment printing on nwcustomapparel.net.

That early machine was just the start. The real magic was still a few years away.

The Breakthrough That Let Dark Fabrics Shine

For a long time, DTG had a glaring weakness. It was fantastic on white or light-colored tees, but try printing a vibrant design on a black shirt, and the colors would just get swallowed by the dark fabric. This was a massive roadblock for anyone whose art truly popped against a dark, moody canvas.

Then, November 2005 happened. The invention of white DTG ink changed the entire game. This wasn't just another color in the palette; it was the foundation.

By first laying down a solid base of opaque white ink, designers could suddenly make their full-color artwork explode with life on any dark garment. Think of it like a painter priming a dark canvas before adding color—it makes everything else stand out.

This single innovation leveled the playing field overnight. Suddenly, a designer hustling out of their Williamsburg studio could create prints with the same jaw-dropping color and quality as a major brand.

Putting the Power in the Creator's Hands

The whole story of DTG's rise feels like it was written for the independent, resourceful spirit of Brooklyn. It’s a classic tale of knocking down technical barriers to get powerful tools into the hands of the people who actually have the ideas.

No more sky-high setup fees for screens. No more being forced to order a thousand shirts just to test one design. DTG wiped those obstacles away.

This shift made creativity, not cash, the most valuable currency. It gave a whole new generation of entrepreneurs the freedom to launch a brand from a laptop, to experiment without risk, and to tell their story, one incredible t-shirt at a time. The journey from a clunky, modified paper printer to a sophisticated digital powerhouse is a tribute to that relentless drive to make a vision real—a feeling every Brooklyn maker knows in their bones.

How Your Digital File Becomes Wearable Art

Every great piece of wearable art begins its life as a simple digital file. But turning pixels into a product you can actually wear? That's where the magic happens. It’s less of an assembly line and more like a modern printmaker's studio, blending high-tech precision with old-school craft to bring a creative vision to life.

Understanding this journey will give you a whole new appreciation for the art form. More importantly, it will help you prep your own designs for truly jaw-dropping results. The whole thing happens in a few key stages, each one crucial for that professional, gallery-quality finish that feels as amazing as it looks.

Stage 1: The Foundation of Pre-Treatment

Before a single drop of ink even thinks about touching the fabric, the garment gets a special pre-treatment. Think of it like a painter priming a canvas with gesso before starting a masterpiece. This solution creates a flawless, smooth surface for the water-based DTG inks, allowing them to sit right on top of the fibers instead of bleeding into them.

This first step is the secret sauce. It’s what makes your colors pop with brilliant, sharp detail, especially on dark-colored shirts. Without it, the final print would look faded and muddy, and all those fine lines and subtle gradients you worked so hard on would vanish.

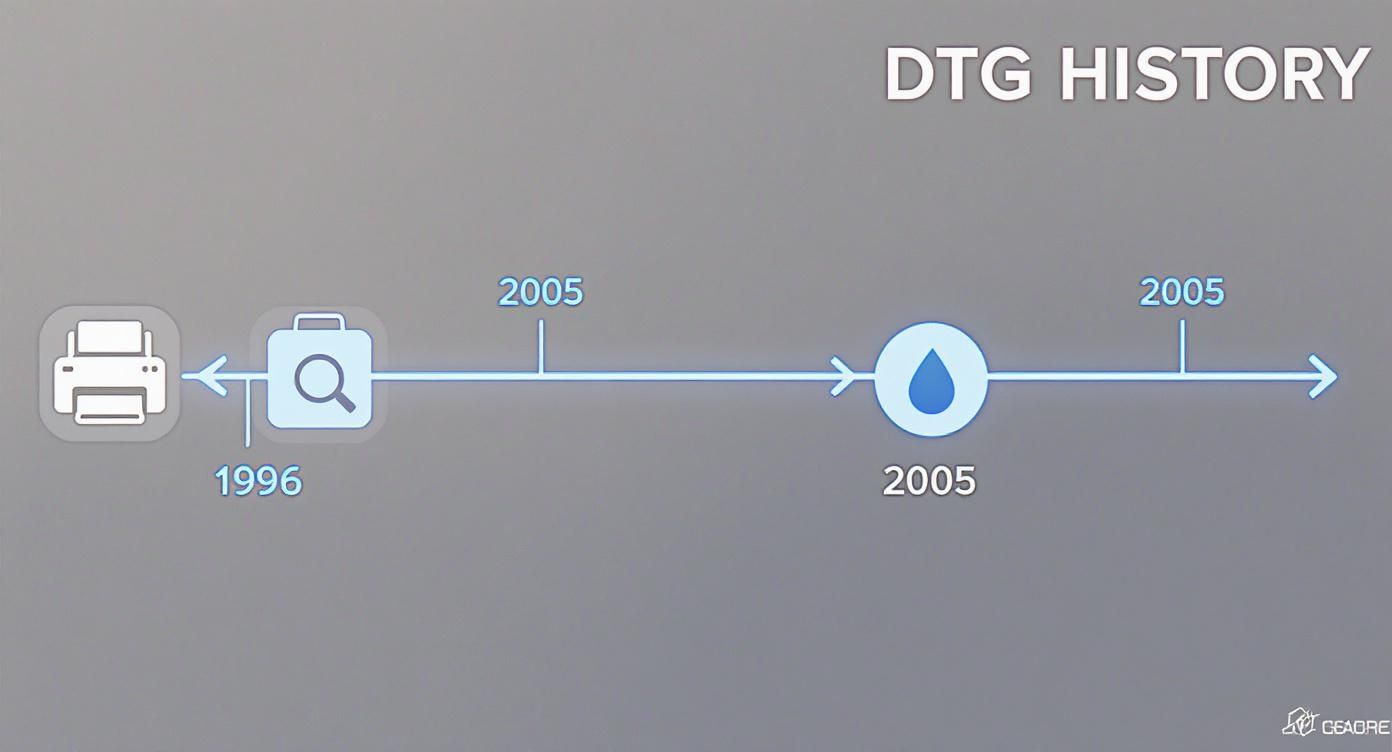

This infographic shows just how far the technology has come.

From the very first printer back in 1996 to the game-changing development of white ink in 2005, this timeline shows the milestones that unlocked the incredible creative power we have today.

Stage 2: The Digital Printing Process

With the "canvas" prepped, we carefully load the garment onto the DTG printer. This is the moment your digital file finally crosses over into the physical world. The printer's super-advanced print heads glide across the fabric, precisely spraying every single drop of cyan, magenta, yellow, and black ink.

If we're printing on a dark shirt, the machine first lays down a base layer of white ink. This acts like that primed canvas we talked about, giving the colors a bright surface to sit on so they can really explode with vibrancy. The printer reads your design file and recreates it with mind-blowing accuracy, blending colors to capture photorealistic detail that old-school methods just can't touch.

This is so much more than just printing. It's about translating artistic data into tangible texture and color. Every pass of the print head is like a brushstroke, guided by your design's code to build the image one tiny droplet at a time.

Stage 3: The Curing and Finalization

Once all the ink is on the shirt, it needs to be locked in for good. The garment is moved to a heat press or a conveyor dryer, where it’s heated to a specific temperature for a set amount of time. This curing process creates a permanent bond between the ink and the cotton fibers.

This is what makes the design durable enough to withstand wash after wash without cracking, peeling, or fading away.

Finally, every single piece gets a thorough quality check. We make sure the colors are spot-on, the placement is perfect, and the final product is a flawless piece of wearable art, ready to get out there and tell its story.

2. Choosing Your Creative Toolkit: DTG vs. Screen Printing

Every artist has to know their tools, right? When you’re bringing a Brooklyn-inspired vision to life on a t-shirt, picking between direct-to-garment (DTG) and screen printing is more than just a technical choice. It’s a creative decision that shapes the entire feel of your brand.

Think of it this way: each method is a different kind of brush, meant for a different kind of masterpiece.

DTG printing is like a digital painter’s finest airbrush. It’s built for stunning complexity, endless color, and all the nuance you can dream of. This is your go-to for capturing a photorealistic shot of the skyline at sunset or the intricate, layered graffiti art of a Bushwick alley. It tells a detailed story.

On the flip side, screen printing is the bold printmaker’s squeegee. It’s all about creating graphics that pop—punchy, vibrant, and with a distinct, tactile feel you can literally run your fingers over. For big runs of an iconic logo or a striking, simple graphic, nothing beats the impact and old-school durability of a screen print.

The Digital Brush vs. The Bold Press

So, which one is right for you? It really comes down to the soul of your brand. Are you creating a wearable gallery piece, something exclusive and rich with detail? Or are you building an iconic, uniform look for your community? The vibe you’re chasing will point you to the right toolkit.

A little-known fact: Brooklyn's official motto is "Een Draght Mackt Maght," a Dutch phrase meaning "Unity Makes Strength." It reflects the borough's history as a collection of diverse villages. DTG, with its ability to create unique, individual pieces, celebrates this diversity, while screen printing, perfect for large runs, embodies the unity.

This choice directly mirrors the creative pulse of Brooklyn itself. One block might have a hyper-detailed mural bursting with a million colors, while the next has a simple, powerful wheatpaste poster that says everything with one stark image. Your t-shirts can do the same.

And if you're truly inspired by that hands-on approach, you can even learn how to screen print t-shirts at home to get your hands dirty and really own the process.

Creative Choice: DTG vs. Screen Printing

To help you find your perfect match, let's put these two powerful methods side-by-side. Think of this as your guide to choosing the right tool for the job—whether you’re painting a detailed portrait or stamping out a bold statement.

| Factor | Direct-to-Garment (The Digital Painter) | Screen Printing (The Bold Printmaker) |

|---|---|---|

| Design Detail | Perfect for photorealistic images, complex illustrations, and unlimited colors. Captures every subtle gradient and fine line. | Best for bold graphics, logos, and text with a limited color palette. Not ideal for complex, multi-color images. |

| Print Feel | Extremely soft and breathable. The ink soaks into the fabric fibers, becoming one with the shirt. | Has a distinct, slightly raised texture. The ink sits on top of the fabric, creating a classic, durable feel. |

| Business Model | Ideal for on-demand printing, small limited-edition drops, and testing new designs with zero upfront cost. | Cost-effective for large bulk orders (50+ units). Setup is intensive, but per-shirt cost drops significantly at scale. |

| Best For | Telling a nuanced, detailed story. Perfect for brands that see each shirt as a unique piece of art. | Creating a bold, iconic statement. Great for brands that want a uniform, recognizable look for events or merchandise. |

Ultimately, both paths lead to incredible results. Your decision hinges on what you want to create and who you want to create it for.

So, what is direct-to-garment printing for a Brooklyn creator? It's freedom. It’s the ability to launch a single, perfect design that tells a complex story without needing to invest in a massive inventory. It’s the power to be as experimental, detailed, and one-of-a-kind as the borough that inspires you.

Fueling Your Creative Business with DTG

This is where the art truly meets the hustle. Think of direct-to-garment printing not just as a technology, but as a whole new way to run your creative business. By getting rid of the steep setup costs that used to come with every single color, DTG flings the doors wide open to the lean, powerful world of on-demand production.

You can now sell first and print later—a nimble strategy that countless modern brands have mastered. It means you can launch a fresh design inspired by a walk through Prospect Park with absolutely zero upfront inventory risk. Forget needing a warehouse full of unsold shirts; all you need is that one great idea.

The On-Demand Revolution

For a small brand, the power to produce a single, perfect shirt whenever you get an order is a total game-changer. This model gives you the freedom to experiment, to test the waters with your boldest ideas, and to change direction without taking a financial hit. It’s the ultimate creative liberty, letting your brand be as dynamic and responsive as the Brooklyn streets that inspire you.

This agile approach also taps into a much bigger conversation. Printing on-demand is a powerful statement against the incredible waste of fast fashion.

- No Overproduction: You only create what people actually buy, wiping out the environmental and financial drag of excess inventory.

- Reduced Waste: It’s a more sustainable choice, using water-based inks and cutting down on the resources devoured by huge apparel runs.

- Mindful Consumption: You’re helping build a culture where people buy unique, meaningful items made just for them, not just another mass-produced shirt.

Scaling from a Single Shirt

The global DTG market has exploded as this technology has put power back into the hands of entrepreneurs. Just look at the rise of e-commerce and on-demand apparel, which has seen double-digit annual growth. Printing directly from a digital file slashes inventory costs and lets you prototype designs in a flash, helping brands scale sustainably from their very first order to a global audience. You can discover more insights about the history of DTG on millcraft.com and see how it’s propping up modern business.

This direct-to-consumer model doesn't just build a profitable business; it builds a genuine connection with your people. When customers know a piece was printed just for them, it feels special, exclusive, and valuable. To really lean into building that bond, check out our guide on increasing customer lifetime value and learn how to turn those first-time buyers into lifelong fans.

DTG gives you the tools to run a business that is both creatively fulfilling and economically smart. It lets a brand born in a Brooklyn studio compete on a global stage, one thoughtfully crafted garment at a time.

Bringing Brooklyn-Inspired Stories to Life

Knowing the "what" of direct-to-garment printing is one thing, but feeling its soul is something else entirely. This isn't just about ink and fabric; it's a storyteller's best friend, perfectly tuned to capture the creative, one-of-a-kind spirit that makes Brooklyn, well, Brooklyn.

This is your chance to turn local stories into wearable art. It's about giving a canvas to the photographers, illustrators, and dreamers who define this borough.

Let's move past the theory and get into some real-world ideas you could run with tomorrow. Think of these as creative launchpads, designed to show you just how powerful DTG can be for telling hyper-local, personal, and artistically rich stories.

Case Study 1: The DUMBO Architectural Series

Picture a local photographer who spends their weekends capturing the raw, industrial beauty of DUMBO. They're obsessed with the high-contrast, black-and-white lines of the Manhattan Bridge looming over cobblestone streets. With DTG, those photorealistic shots can be printed directly onto high-quality, heavyweight cotton tees.

Suddenly, it’s not just merchandise. It’s a wearable gallery. Each shirt tells a story of light and shadow, transforming gritty architecture into high-end fashion. Because DTG absolutely nails grayscale tones and intricate detail, every subtle element of the original photo shines through, creating a sophisticated piece that speaks to art lovers and proud locals alike.

Case Study 2: The Greenpoint Floral Collection

Now, imagine an illustrator in Greenpoint known for their incredibly detailed floral designs. Did you know Greenpoint was once known as the "Garden Spot" of Brooklyn? It was famous for its farms and market gardens. This bit of history adds a layer of meaning to a modern floral collection.

DTG makes it effortless for an artist to drop a limited-edition series where every shirt features a different botanical illustration, printed with stunning, vibrant color. Better yet, they can offer a huge range of designs without having to pre-order a single shirt, celebrating the hidden, lush gardens of their neighborhood on-demand.

This is where DTG truly comes alive. It frees artists to print their most ambitious, detailed work without compromise. The technology doesn't limit the vision; it brings it to life.

Case Study 3: The Park Slope Family Brand

Finally, think about a parent in Park Slope who wants to bottle up the whimsical, playful energy of their community into a brand. They dream of a line of personalized kids' tees with charming graphics where the child's name is woven right into the design.

For this, DTG is the only way to go. It’s built for one-off customization, making every single piece totally unique. A customer can order a shirt with a specific name and graphic combo, and you can print it right then and there. This kind of personal touch forges a real connection, turning a simple t-shirt into a cherished keepsake.

Got Questions About DTG? We've Got Answers.

Even when you're fired up and ready to create, a few practical questions can pop up. It's totally normal. Here, we'll tackle the most common things creators ask, giving you the clear, straightforward answers you need to get your next Brooklyn-inspired project off the ground with confidence.

What Fabrics are Best for DTG?

For truly vibrant, lasting prints, DTG loves natural fibers. 100% cotton is the undisputed champion here. Its fibers act like a sponge, perfectly soaking up the water-based inks and locking in every last detail of your design.

High-cotton blends work great, too. You can even print on a 50/50 blend, but be aware that the colors might come out a bit softer, with more of a vintage vibe. That can be a really cool look if it's what you're going for! Just steer clear of 100% polyester or other pure synthetics—the ink simply won't bond to the fabric correctly.

How Do I Take Care of My DTG Shirt?

You’ve created a piece of wearable art, and a little care goes a long way in keeping it looking amazing. The golden rule? Always wash it inside out in cold water on a gentle cycle. This simple step protects the print from rubbing against other clothes and the inside of the machine.

Pro Tip: Skip the bleach and harsh detergents entirely, as they can be brutal on the inks. When it comes to drying, your best bet is to tumble dry on low or, even better, hang it up to air dry.

This gentle routine will help prevent any cracking or fading, keeping your design fresh for years. For an even deeper dive, check out our guide on how to wash graphic tees and keep them looking like you just bought them.

Is DTG Printing an Eco-Friendly Option?

Yes, it really is. When it comes to printing on apparel, DTG is one of the most sustainable choices you can make. The inks are typically water-based and biodegradable, which is a huge step up from the plastisol inks used in other methods.

Even better, the entire print-on-demand model that DTG makes possible is a game-changer for reducing waste. You only print what you need, when you need it. This means no more guessing games, no more boxes of unsold inventory collecting dust. It's a smarter, more responsible way to build a brand—one thoughtfully made piece at a time.

Ready to bring your own Brooklyn story to life? At The Brooklyn Initiative, we celebrate the borough's unique culture with limited-edition tees that are as bold and original as you are. Explore our collection and find your new favorite shirt.